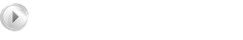

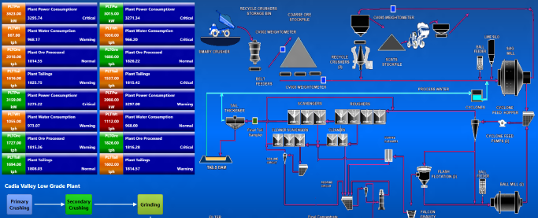

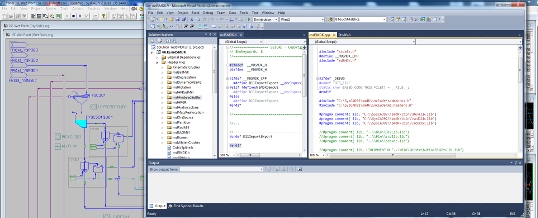

This is part three of Our Simulation Platform blog. In this month’s post, we discuss how we integrate process control and plant operating philosophies into process simulations.

You can catch up on our previous blog topics here:

Part 1: Our Simulation Platform

Part 2: Multicomponent comminution modelling

So, onto the topic of process control and simulation. The role of process control and operating philosophies (aka human control) in mineral processing plant simulation is ...

Continue Reading →JUN